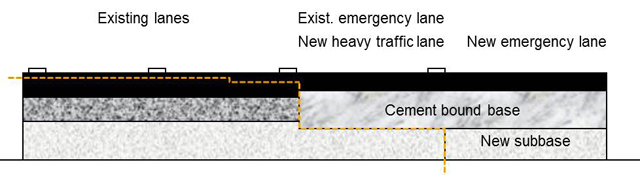

The Danish Road Directorate has, in cooperation with a consortium of contractors consisting of Barslund A/S, K.L. Kristensen A/S the SR Group, introduced a new construction method which exploits the existing materials in the road, as well as providing a very resistant road surface for heavy traffic. The existing gravel materials and asphalt on the emergency lane are upgraded to a hydraulically bound layer, which then forms the base layer of the new heavy load lane and the emergency lane. The road is then finished with an asphalt surface layer.

Motorway widening near Vejle

Over the next two years, the motorway from the Skærup junction to Vejle South will be widened by one extra lane in each direction. It is one of Denmark’s busiest stretches of motorway, carrying a great deal of heavy traffic. The construction work began last year with reinforcing of the emergency lane for the temporary traffic load. This summer traffic flow will operate as a 3 1 model in which one of the southbound lanes will be transferred to the other side of the road, providing space for widening work on the southbound section.

Construction method

It was planned that the road widening on the section would involve removing the existing emergency lane, prior to installation of a new lane and then lane widening with a new emergency lane. This widening would be laid as a 100 per cent new road by excavating a new formation and then creating the two lanes with exclusively new materials, but it makes more sense to use the materials already in the existing emergency lane, which consists of approximately 6 cm asphalt on a 10 cm unbound gravel base and a 50–80 cm subbase.

During the tender process it was decided to gather tenders for traditional construction and an alternative pricing for the construction of a base layer with a cement stabilisation of the existing materials. It emerged that the price for this alternative was attractive, and the decision was made to undertake the project with a “hydraulically bound base layer”, known as HBB (see fig. 1). The hydraulically bound base layer has recently been reintroduced by the Danish Road Directorate following progress made on development projects and formulation of work specifications.

The principles for road widening construction work were as follows:

- excavating down to new formation level to the right of the existing emergency lane

- laying new sub-base materials for the new emergency lane

- milling the asphalt from the existing emergency lane

- materials from the existing emergency lane (asphalt and gravel) are then laid over both old and new emergency lanes

- new gravel materials are added up to a level equal to the underside of the asphalt to be laid

- any necessary watering of materials to ensure optimal water content

- laying of cement on the widened section

- homogenisation and mixing with cement to a depth of 25 cm

- levelling and compaction

- transverse crack inducing

- sealing of cement bound surface

- laying 20 cm of asphalt layer (base, binder and wearing course).

The longitudinal joint between old and new pavement is ensured by stepped assembly and net reinforcement.

The first part of the widening work was carried out in early June 2012 and the remaining section of the southbound carriageway will be carried out in autumn the same year. Northbound carriageway work is planned following the same principles next year. The entire widening project will therefore be completed in the autumn of 2013.

Crack inducement

Crack control is an important element to ensure good function of this pavement type. Unlike a flexible asphalt layer, the cement bound layer has a property to create transverse cracks every 10–20 metres as a result of shrinkage and temperature changes. This can however be avoided during the construction, if closer spaced cracks are induced, generating less crack movement. Specifically, this is done using a drag plate which lays a transverse track at approximately one third of the depth, with a distance of no more than 2.5 metres (see fig. 3). This creates a weakened transversal section pokies which gives a fine crack through the remainder of the layer. The movements in these layers are subsequently so small that reflection cracks traditionally found in so called semi-rigid pavements should not form.

The function of the layers in the new road

Denmark has not had a tradition for constructing fully load bearing emergency lanes, but rather construction of a relatively thin pavement only suited to occasional usage and light traffic. In other countries such as Germany, emergency lanes with full pavement have been built for many years. This gives much greater flexibility with relation to renovation work and future traffic.

Design calculations have been carried out for the road widening using hydraulically bound base layers which show that the bearing capacity is significantly better than for an asphalt construction where the high traffic volume on the section would require an asphalt thickness of approx. 32 cm. In comparison with a traditional motorway pavement, the function of a cement bound layer is to combine and replace the unbound gravel base and the lower asphalt base layer.

Perspectives

In choosing this construction method, a very strong pavement for both the new heavy-load lane and the new emergency lane is achieved, which can be used for traffic during any future construction or maintenance work, or for any temporary or permanent function as a regular traffic lane.

It was originally estimated that the pavement construction would be somewhat cheaper than a traditional asphalt construction. A certain amount of follow-up work is required, for example around gully pots, reducing potential savings in the construction budget. An improved life cycle cost for the road is still expected, because experience suggests that the rigidity and significant load-bearing qualities of the road construction should give a longer life-span for all the road layers.

A similar construction method is expected to be used for the forthcoming widening of the motorway at Funen.

A comparable upgrading is also being considered as a general method to provide a cost-effective increase in capacity on existing motorways. The idea is to increase the strength of the emergency lane using in-situ cement stabilisation of existing gravel materials, without construction of new emergency lanes. As such, it is possible (without increasing the total area of the road surface) to provide the road with a lane capable of bearing full traffic on a permanent basis or in peak traffic times, for a relatively limited cost. This solution would also require consideration of the construction of escape bays to allow the possibility of emergency stopping, and also consideration of how the emergency services can reach any road traffic accidents.

Figure 1: Schematic diagram of road widening. The dotted line illustrates the border between the old road and the new/upgraded materials.

Figure 1: Schematic diagram of road widening. The dotted line illustrates the border between the old road and the new/upgraded materials.

Figure 2: Mixing cement in the widened road section. Photo: Michael Nordentoft

Figure 2: Mixing cement in the widened road section. Photo: Michael Nordentoft

Figure 3: Crack inducement in a cement bound base layer. Photo: Michael Nordentoft

Figure 3: Crack inducement in a cement bound base layer. Photo: Michael Nordentoft

Contact

Finn Thøgersen, fit@vd.dk

Kai Egede Jensen, kegj@vd.dk

DRD, Denmark

Follow us: